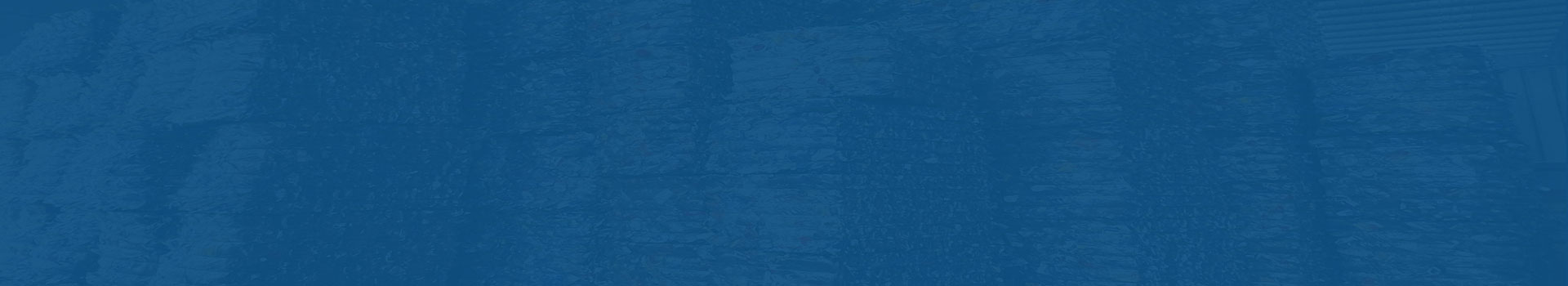

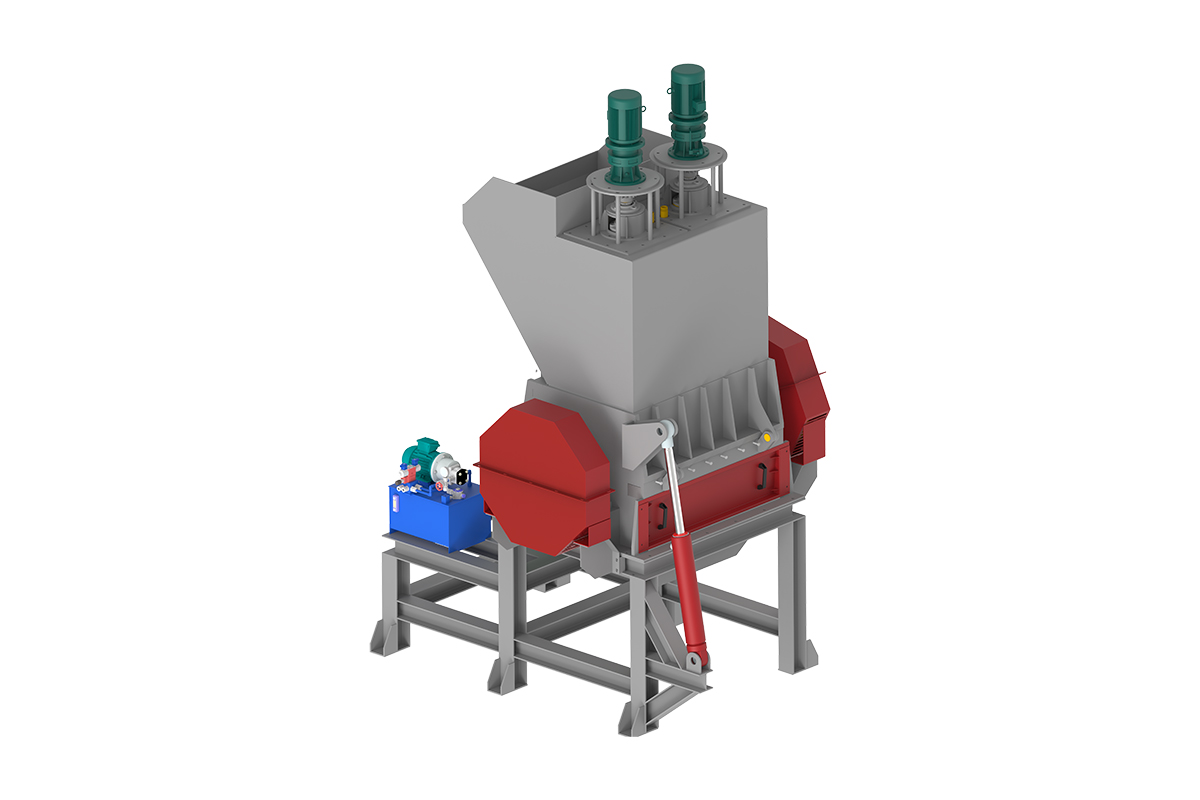

Double Shaft Shredder

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

Double Shaft Plastic Shredder

- Product Details

- Basic Parameters

- Technical Specifications

Introduction of Double Shaft Plastic Crusher Machine

Double Shaft Plastic Crusher Machine is suitable for shredding various plastic materials and can meet the solid waste recycling requirements of different industries.

A double-shaft self-pressurizing plastic shredder generally refers to a Double Shaft Plastic Crusher Machine. Instead of cutting with high-speed rotating blades, it crushes plastic materials using low-speed, high-torque blades. The following is a detailed introduction to it:

Working Principle:

A double-shaft plastic shredder is equipped with two intermeshing hexagonal main shafts. Bearings are installed at both ends of the main shafts, which are driven to rotate by a motor and a reduction gear. This rotation makes the blades on the two shafts mesh with each other, shearing, tearing, and extruding the materials to achieve the purpose of shredding. When there is excessive feeding or the material size is too large, the automatic reversal device in the electronic control part will make the machine run in reverse and stop, so as to prevent damage to the blades or the motor.

Structural Features

Blades: The blades are usually made of high-wear-resistant alloy steel (such as SKD11 steel) and undergo heat treatment, featuring excellent wear resistance and strength. Blades of different thicknesses and shapes can be selected according to different materials and shredding requirements.

Main Shafts: Forged from special alloy tool steel, the main shafts undergo precision machining and multiple heat treatment processes. They can withstand large torque and provide strong power for shredding.

Machine Body: The main body is welded from high-quality steel plates, and undergoes stress relief treatment and overall machining. This ensures the equipment operates stably for a long time under heavy loads.

Application Scope

It is suitable for shredding various plastic materials, such as plastic barrels, plastic bottles, plastic pipes, and plastic films. It can also be used to shred multiple solid waste materials including rubber, fibers, paper, wood, automobile tires, and waste home appliance casings. It can meet the solid waste recycling requirements of multiple industries such as plastic recycling, wood processing, and electronic waste management.

Performance Advantages

Efficient Shredding: The double-shaft design and special blade structure enable it to efficiently shred various plastic materials with a large processing capacity. Depending on different models and configurations, the hourly processing capacity can range from several hundred kilograms to dozens of tons.

High Stability: With professionally designed shafts and blades, it can withstand high radial loads, operate stably, and produce low noise. At the same time, the equipment is equipped with an intelligent control system that can monitor the shredding status and automatically adjust forward and reverse rotation to ensure stable operation of the equipment.

Good Safety: It is usually equipped with an emergency stop button, safety protection devices, etc., which can effectively prevent accidental injury to operators and ensure the safety of equipment and personnel.

| Model | Motor power(kw) | Hydraulic station power(kw) | Diameter(Ф) | Speed(r/min) | Screen aperture(mm) | Weight(kg) |

| 800 | 45kw | 0.75kw | Ф570mm | 530r/min | Customizable | 2020kg |

| 1000A | 55kw | 1.5kw | Ф620mm | 556r/min | Customizable | 3250kg |

| 1000B | 55-75kw | 1.5kw | Ф680mm | 556r/min | Customizable | 3850kg-3950kg |

| 1200A | 75kw | 1.5kw | Ф660mm | 556r/min | Customizable | 4800kg |

| 1200B | 90-112kw | 1.5kw | Ф800mm | 556r/min | Customizable | 5050kg-5320kg |

| 1600 | 162kw | 3kw | Ф800mm | 500r/min | Customizable | 6500kg |

● Materials: Both the housing and blade holder are made of 45-gauge steel for high strength and resistance to deformation.

● Sturdy mortise and tenon welded steel structure.

● Manganese steel screen for wear resistance.

● Heavy-duty pulleys.

● Hydraulic flap for easy access and maintenance.

● Different blade roller configurations maximize productivity and service life.

● Drum types: Splayed blade roller, Slotted blade roller, Hanako blade roller, etc.

English

English