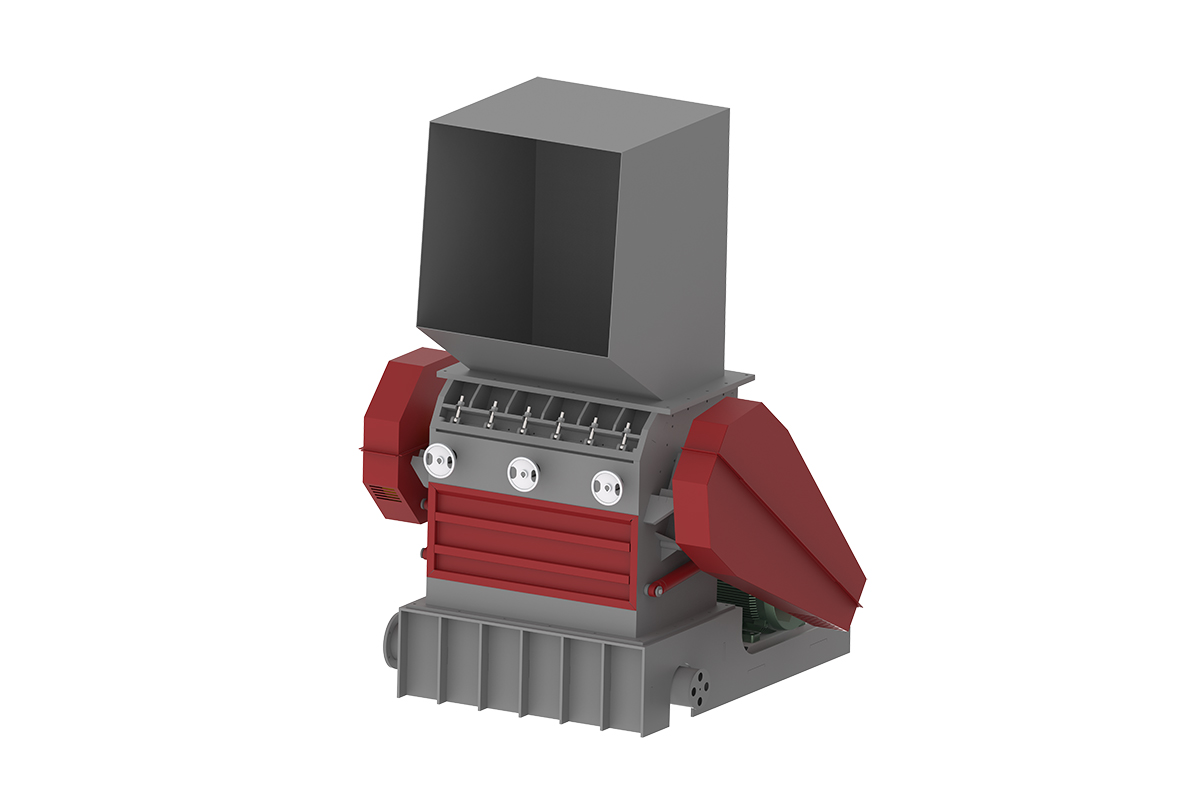

Hammer Mill Crusher

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

Heavy Crusher

- Product Details

- Basic Parameters

- FAQ

Heavy Crusher Product Introduction

This Heavy Crusher is a professional equipment developed for plastic material recycling and processing scenarios. With its efficient crushing performance and wide adaptability, it has become one of the core equipment in the solid waste recycling system of various industries.

Core Application Scope

Specially designed for various plastic materials, it can efficiently process plastics of various forms and materials, including but not limited to:

Bulk plastics: such as plastic blocks, injection molding scraps, and thick-walled plastic products (e.g., plastic buckets and pallets);

Film-forming plastics: such as plastic film, plastic bags, plastic packaging films, and other materials that easily tangle;

Hard and brittle plastics: such as PVC pipes, PPR pipe fittings, ABS plastic parts, and plastic sheets;

Waste plastic products: such as recycled materials like used home appliance housings, plastic automotive parts, and used plastic containers.

Industry Adaptability

It can accurately match the solid waste recycling needs of different industries and provide solutions for the reduction and reuse of plastic waste in various fields. Typical applicable industries include:

Plastics Processing Industry: Processing scraps and substandard products generated during the production process, enabling raw material recycling and reducing production costs.

Packaging Industry: Shredding waste plastic packaging film and packaging barrels to address the problem of packaging waste accumulation and meet environmental protection requirements.

Automotive Industry: Recycling plastic parts (such as dashboards and door panels) generated during vehicle disassembly, contributing to green recycling efforts in the automotive industry.

Electronic and Electrical Industry: Processing used home appliance casings and plastic components, integrating environmentally friendly recycling processes to achieve resource recovery.

Municipal Environmental Protection Industry: Participating in the pre-processing of urban plastic waste (such as used plastic bags and bottles), laying the foundation for subsequent resource utilization.

Core Working Principle

It adopts the "high-speed cutter cutting and crushing" technology, and realizes the crushing processing of plastic materials through a stable and efficient mechanical structure. The specific process is as follows:

Feeding stage: Plastic materials enter the crushing chamber through the feed inlet. The feed guiding structure equipped with the equipment can prevent material blockage and ensure smooth feeding;

Cutting and crushing stage: The high-speed rotating cutters (usually multi-composite alloy cutters with high hardness and strong wear resistance) in the crushing chamber cooperate with the fixed knife set to quickly shear, impact and tear the materials, breaking large or irregular plastics into uniform granular materials;

Discharging and screening stage: The crushed materials are screened through the screen at the bottom of the equipment. Particles that meet the particle size requirements fall through the screen and enter the subsequent conveying or storage link; if the particle size of the materials does not meet the requirements, they will remain in the crushing chamber for further crushing until they meet the standards.

By optimizing the tool layout and speed design, the equipment not only ensures the crushing efficiency, but also reduces the overheating and adhesion problems of plastic materials during the crushing process, ensuring the quality of the crushed materials and meeting the needs of subsequent granulation and recycling processing.

| Model | Motor power(kw) | Hydraulic station power(kw) | Diameter(Ф) | Speed(r/min) | Screen aperture(mm) | Weight(kg) |

| 800 | 45kw | 0.75kw | Ф570mm | 530r/min | Customizable | 2020kg |

| 1000A | 55kw | 1.5kw | Ф620mm | 556r/min | Customizable | 3250kg |

| 1000B | 55-75kw | 1.5kw | Ф680mm | 556r/min | Customizable | 3850kg-3950kg |

| 1200A | 75kw | 1.5kw | Ф660mm | 556r/min | Customizable | 4800kg |

| 1200B | 90-112kw | 1.5kw | Ф800mm | 556r/min | Customizable | 5050kg-5320kg |

| 1600 | 162kw | 3kw | Ф800mm | 500r/min | Customizable | 6500kg |

Q1: The crushing efficiency of the heavy crusher suddenly decreases, and the size of the crushed plastic materials is uneven. What might be the reasons and how to solve it?

A1: There are 4 main reasons: ① Its blade edges become dull after long-term use, failing to cut plastic materials effectively; ② Its screen holes are blocked by sticky plastic residues or fine particles, which prevents qualified plastic particles from being discharged; ③ The feeding speed is too fast, so plastic materials are not fully cut in the crushing chamber; ④ Its motor belt is loose or the power voltage is unstable, leading to insufficient blade rotation speed.

Solutions: First, check the blades—slightly worn ones can be sharpened for repair, while severely worn ones should be replaced with matching parts. Then, clean the screen (use a high-pressure air gun or special solvent to remove sticky plastic residues). Next, adjust the feeding rhythm to avoid overloading. Finally, check the tightness of the motor belt and calibrate the power supply voltage (it must meet the equipment’s rated value).

Q2: The heavy crusher makes harsh abnormal noises or has obvious vibration during operation. What issues should be checked?

A2: Focus on checking 4 aspects: ① Its blades are installed incorrectly, or the gap between the blades and the fixed knife set is improper (too large/too small), causing collision during operation; ② Its anchor bolts are loose, making the machine body unstable and resulting in vibration; ③ Hard objects such as metals and stones are mixed into the crushing chamber and collide with the blades; ④ Its motor bearings lack lubrication or are worn.

Solutions: After stopping the equipment, calibrate the position and gap of the blades. Tighten the anchor bolts with a wrench. Cut off the power and clean the hard objects in the chamber (plastic materials must be screened before feeding in subsequent operations). Add special lubricating grease to the motor bearings, and replace the bearings if they are severely worn.

Q3: The heavy crusher’s feed inlet is frequently blocked, and plastic materials cannot go down. How to deal with this?

A3: First, identify the causes of blockage: ① The plastic material humidity is too high (e.g., plastic films absorb moisture and stick together) or the material size is too large, exceeding the applicable range of the feed inlet; ② Plastic materials in the crushing chamber are not discharged in time, causing "reverse blockage" at the feed inlet; ③ The guide plate at the feed inlet is deformed, which hinders the downward sliding of plastic materials.

Solutions: Dry the wet plastic materials first, and pre-cut large-sized materials to meet the feed requirement. Run the equipment idly to discharge the accumulated materials in the chamber before resuming feeding. Straighten or replace the deformed guide plate of the feed inlet, and ensure the inclination angle is conducive to material sliding (usually 30°-45°).

Q4: The heavy crusher’s motor frequently trips due to overload, and the equipment cannot start or suddenly stops during operation. How to solve this?

A4: First, analyze the reasons for tripping: ① The single feeding amount is too large, exceeding the rated load of the motor; ② Hard objects mixed into the chamber get stuck in the blades, causing a sudden increase in motor load; ③ The motor wiring is loose, the cable is short-circuited, or the electrical components are faulty; ④ The motor winding is burned out, or the thermal relay parameters are set incorrectly.

Solutions: Reduce the feeding amount and adopt the "small amount and multiple times" feeding method. Cut off the power, clean the stuck materials in the chamber, and check the motor wiring—replace aging cables if necessary. Verify the thermal relay parameters (they must match the motor’s rated current). Use a megohmmeter to test the motor winding—if the insulation resistance is lower than 0.5MΩ, the winding needs to be repaired or the motor replaced.

English

English