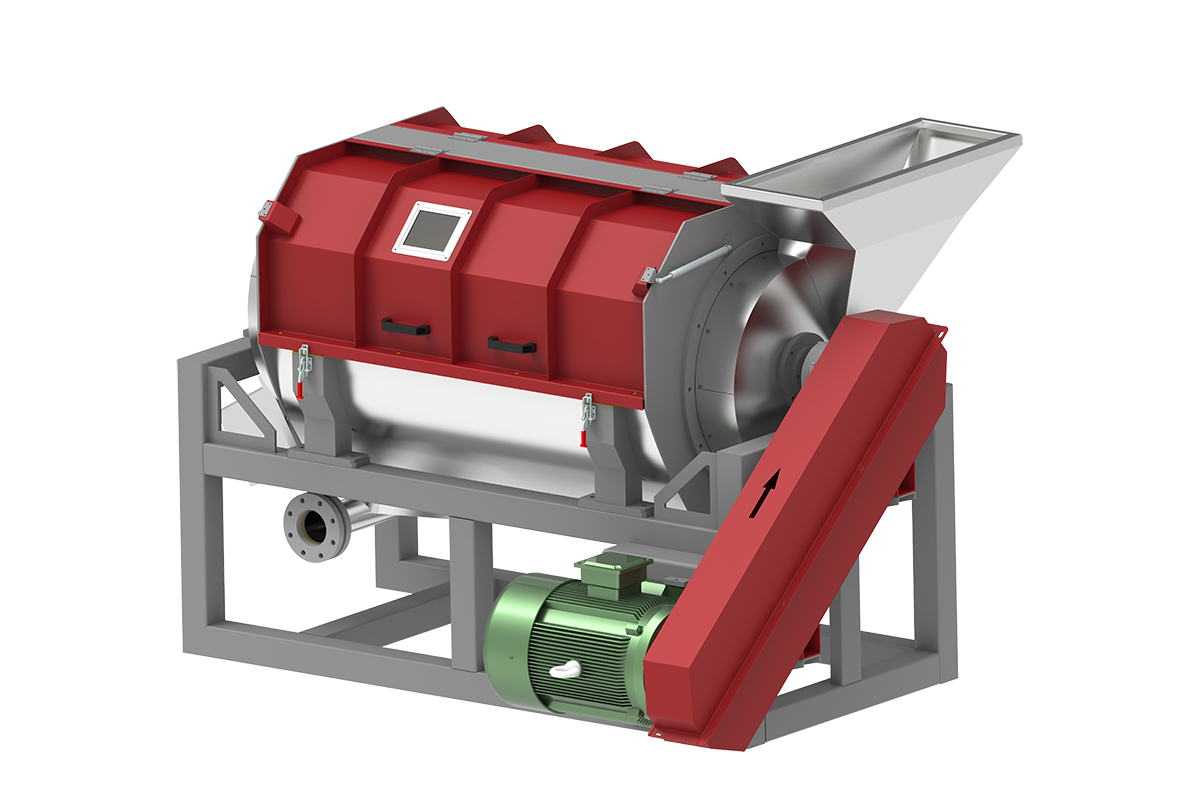

Horizontal Centrifugal Dryer

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

Horizontal Dehydrator

- Product Details

- Basic Parameters

Based on your description, this horizontal dehydrator features ultra-high rotation speed, high dehydration efficiency, and friction resistance. It is suitable for various types of plastics. Its stainless steel full-screen mesh structure, precision-machined main shaft with highly wear-resistant blades, and bearings that can withstand high loads without easily overheating enable it to efficiently rub, clean, and dehydrate various plastics in high-demand settings. The relevant introduction is as follows:

Working Principle

Generally, a centrifugal force is generated by a high-speed rotating drum or rotor to throw the moisture in materials toward the screen mesh. The moisture is discharged through the screen mesh, while plastic particles are retained, thereby achieving dehydration. Some horizontal dehydrators may also incorporate vibration or other methods to further enhance dehydration efficiency and effectiveness.

Structural Features

Stainless Steel Full-Screen Mesh Structure: The full-screen mesh structure made of stainless steel offers excellent corrosion resistance and wear resistance. It can withstand the friction and cleaning processes of various plastics while ensuring dehydration performance.

Precision-Machined Main Shaft with Highly Wear-Resistant Blades: The main shaft undergoes precision machining to ensure rotational stability and accuracy. The blades are made of highly wear-resistant materials (such as hard alloys), which can resist friction and wear from plastic particles during long-term use, extending the service life of the equipment.

Bearings with High Load-Bearing Capacity and No Easy Overheating: The equipped bearings can withstand high loads, meeting the operational requirements of the horizontal dehydrator during high-speed rotation and large-volume material processing. Meanwhile, special heat dissipation designs (such as water-cooled structures) may be adopted to effectively reduce the temperature of the bearings, preventing them from overheating easily and ensuring the normal operation of the equipment.

Performance Advantages

Ultra-High Rotation Speed and High Dehydration Efficiency: With ultra-high rotation speed, it can generate strong centrifugal force to quickly separate moisture from plastic materials. This high dehydration efficiency significantly shortens dehydration time and improves production efficiency.

Wide Application Range: Owing to its friction resistance, it is suitable for various types of plastics, including soft plastics (such as films, jumbo bags, and woven bags) and rigid plastic particles.

Integrated Cleaning and Dehydration: While dehydrating, it can efficiently rub and clean plastics to remove impurities and stains on the plastic surface, realizing the dual functions of cleaning and dehydration and meeting the needs of high-demand settings.

| Model | Power(kw) | Diameter(Ф) | Blade(Group) | Speed(r/min) | Weight(kg) |

| 600 | 30kw | Ф470mm | 8 | 1480r/min | 1460kg |

| 700 | 37kw | Ф660mm | 8 | 1480r/min | 1484kg |

| 800 | 45kw | Ф680mm | 8 | 1480r/min | 2328kg |

English

English