What is Double Shaft Plastic Shredder?

2025-08-04 16:18:56

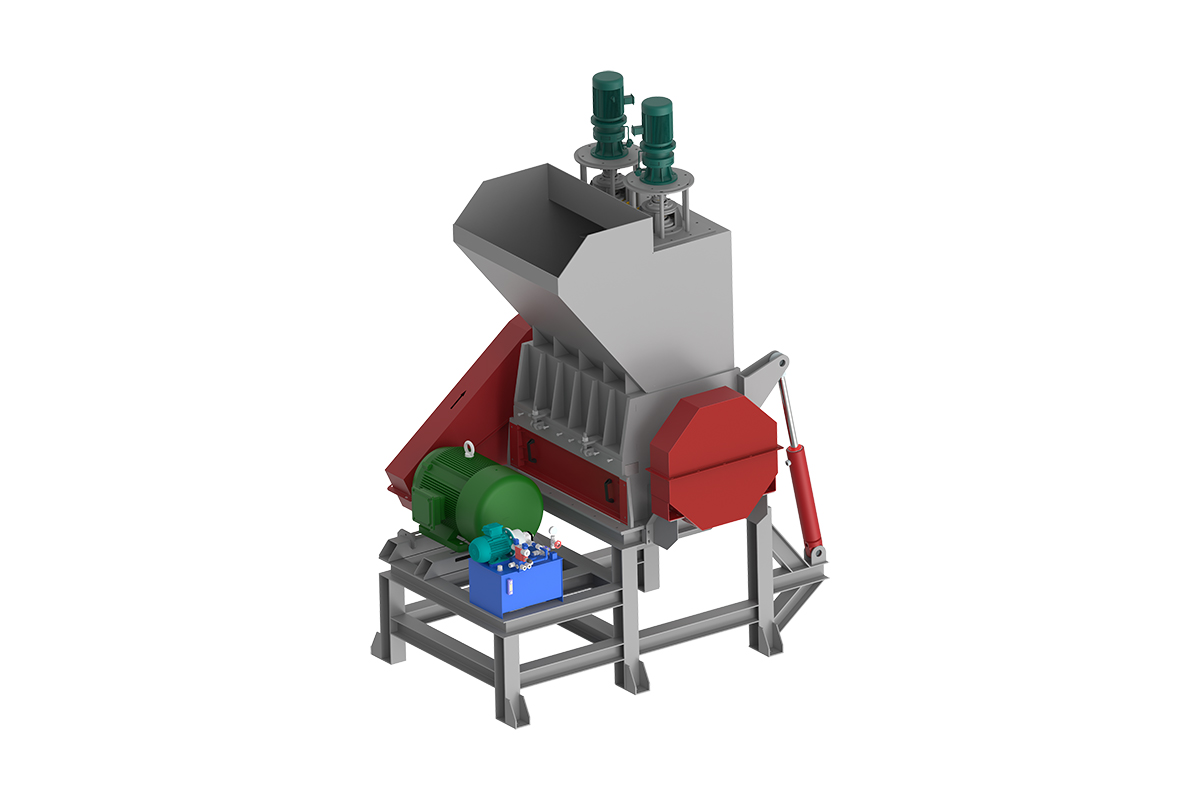

A double-shaft plastic shredder is a kind of industrial equipment mainly used for shredding plastic materials. It has the following characteristics and working principles:

Main Features

Powerful and Efficient Shredding: It is equipped with two counter-rotating shafts, and each shaft is equipped with multiple powerful cutting blades. The dual-shaft design with interlocking shear blades ensures even, powerful, and efficient shredding of bulk materials.

Versatile Processing: Capable of processing various plastic materials, such as soft plastics like plastic films and woven bags, as well as hard plastics like plastic bottles and barrels. In addition, it can also handle other materials such as rubber tires, wood, automotive parts, and electronic waste.

Robust Construction: Built with high-strength alloy steel and a durable frame to ensure long-term stable operation in harsh industrial environments. Some models are also equipped with an auto-reverse system, which automatically reverses the rotor direction when overloaded or jammed to protect the blades and drive system from damage.

Advanced Safety Features: Equipped with emergency stop buttons, safety guards, and PLC-based overload protection devices to ensure the safety of operators.

Working Principle

The core of the double-shaft plastic shredder is two parallel-installed, sturdy rotating shafts. Driven by a powerful motor, the two shafts rotate in opposite directions at a relatively low speed (high torque). The materials are fed into the working area between the two shafts through the feeding hopper. The rotating blades bite and grab the materials like "claws", and the materials are forcibly cut and torn by the strong shear force at the intersection of the blades of the two shafts (shearing point). At the same time, the materials are also strongly squeezed between the blades and between the blades and the lining plate of the cavity, and are further broken. When the size of the broken material fragments is smaller than the gap between the blades or the aperture of the screen, they are discharged from the bottom. Materials that do not meet the size requirements will continue to be shredded in the cavity until they meet the discharge requirements.

Application Fields

It is widely used in the field of plastic recycling, such as processing waste plastic products into small particles for subsequent washing, melting, and granulation; it can also be used in wood processing, e-waste management, and other industries to crush and process corresponding waste materials to facilitate resource recovery and utilization.

English

English