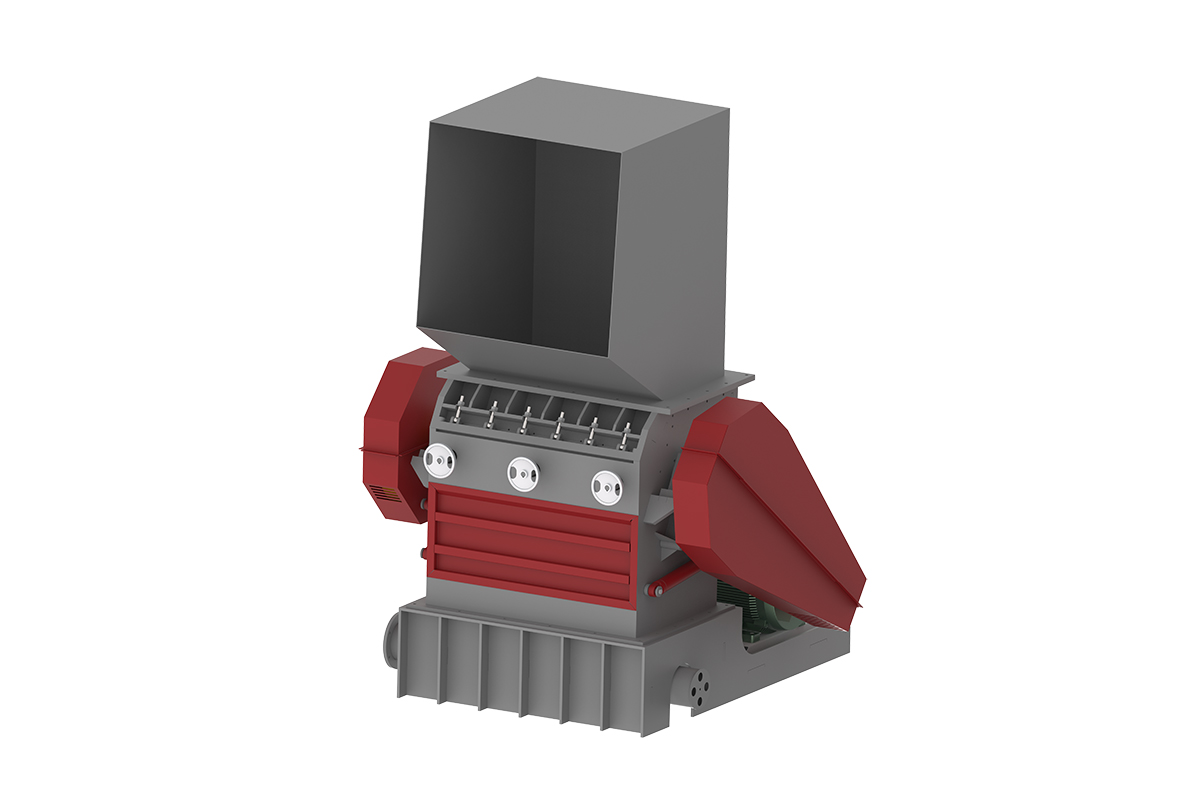

Maintenance Methods for Heavy Crushers

2025-08-04 16:19:05

Heavy crushers operate under harsh conditions (high load, strong impact), so targeted maintenance is critical to avoid unplanned downtime, extend service life, and keep crushing efficiency stable. Below is a balanced breakdown—concise but covering all essential details:

Daily Inspection (Non-Negotiable Basic Checks)

Daily checks prevent small issues from escalating into major failures, taking ~20–30 minutes total:

Pre-operation (10–15 mins)

- Tighten loose bolts (frame, feed hopper, crushing chamber) with a torque wrench (key for rotor shaft/frame connections).

- Inspect crushing elements (jaw plates, cone liners, hammers): replace if wear exceeds limits (e.g., jaw plate thickness reduced by 50%, hammer heads cracked).

- Clear blockages in the hopper/chute (avoid uneven feeding) and test emergency stops/safety interlocks (must work instantly).

- Check lubricant levels (gearboxes, bearing housings) via sight glasses—add oil if below the "min" mark, ensuring no turbidity.

In-operation (real-time monitoring)

- Listen for abnormal sounds (grinding = bearing wear; knocking = loose parts) and watch for excessive vibration (unbalanced hammers = rotor issue).

- Measure temps with an infrared thermometer: bearings ≤70°C (overheat = poor lubrication/wear); gearboxes ≤60°C (overheat = oil leak/gear misalignment).

- Ensure steady feeding (no overfeeding = avoid overload; no underfeeding = avoid low efficiency) and consistent discharge particle size (sudden coarseness = worn liners).

Post-operation (5–10 mins)

- Clean residual material from the crushing chamber/hopper (use compressed air or a shovel—no sharp tools to scratch liners).

- Mark severely worn parts (e.g., cracked impact plates) for replacement; log operating data (time, temps, abnormal signs) for traceability.

Periodic Maintenance (Planned Deep Care)

Adjust frequency based on usage (e.g., 24-hour operation needs more frequent checks) and follow the manufacturer’s guidelines:

Weekly (1–2 hours)

- Replace oil filters in lubrication systems (keeps oil clean).

- Adjust drive belt tension (loose = slipping; tight = bearing strain) and check hydraulic systems (cone/jaw crushers) for leaks—top up hydraulic oil if needed.

Monthly (2–3 hours)

- Disassemble bearings (rotor, drive end) to check for rust/pitting—replace if inner/outer rings are damaged or clearance exceeds limits.

- Calibrate crushing gaps (e.g., jaw plate gap, cone mantle gap) to meet particle size requirements.

- Replace aging seal rings (bearing housings, gearboxes) to prevent dust/oil leakage.

Quarterly (4–6 hours)

- Inspect the frame/base for cracks (use ultrasonic testing on key welds)—repair cracks with the manufacturer’s specified welding process.

- Overhaul gearboxes: drain old oil, clean the interior (remove sludge), check gears for tooth wear/chipping, and refill with specified-grade oil.

- Align motor/rotor shafts (use a laser tool—misalignment causes belt wear/bearing damage).

Annual (8–10 hours)

- Replace near-worn parts (liners, hammers, toggle plates) even if not severely damaged (avoids sudden failures in peak production).

- Test electrical systems: check motor winding insulation (no short circuits) and contactors (no arcing damage)—replace faulty sensors/relays.

- Run a 1–2 hour rated load test: verify capacity, particle size uniformity, and power consumption—adjust feed rate/gaps if deviations occur.

Key Component Maintenance (Targeted Protection)

Crushing elements: Rotate/flip symmetric parts (e.g., jaw plates, impact plates) every 2 weeks for even wear (extends life by 30–50%); replace per manufacturer limits (e.g., hammer weight reduced by 15%).

Bearings: Use only specified lubricants (no mixing types—causes chemical reactions); replace seals monthly to block dust/water (contaminated bearings fail 3–5x faster); install new bearings with pullers (no hammering—avoids shaft damage).

Lubrication systems: Change oil per cycle (gearboxes every 2,000 operating hours; bearings every 500 hours); replace air/oil filters during oil changes (clogged filters = oil starvation); fix leaks at flange/pipe joints immediately.

Operational Precautions (Preventive Habits)

Control feeding: Use a vibrating feeder for uniform input—no overfeeding (causes overload) or underfeeding (wastes energy).

Block impurities: Install magnetic separators/metal detectors at the feed inlet to stop steel bars/concrete rods (avoids cracked liners/bent rotors).

Follow start/stop order: Start = discharge conveyor → crusher → feed conveyor; stop = reverse order (prevents material buildup in the chamber).

Train operators: Ensure they recognize abnormal signs (overheating, strange noises) and know how to use emergency stops—no untrained personnel allowed.

Final Note: Always refer to the manufacturer’s manual for model-specific details (e.g., bolt torque values, oil grades)—this ensures maintenance accuracy.

English

English