Comprehensive Introduction to Separation Machine

2025-08-04 16:23:00

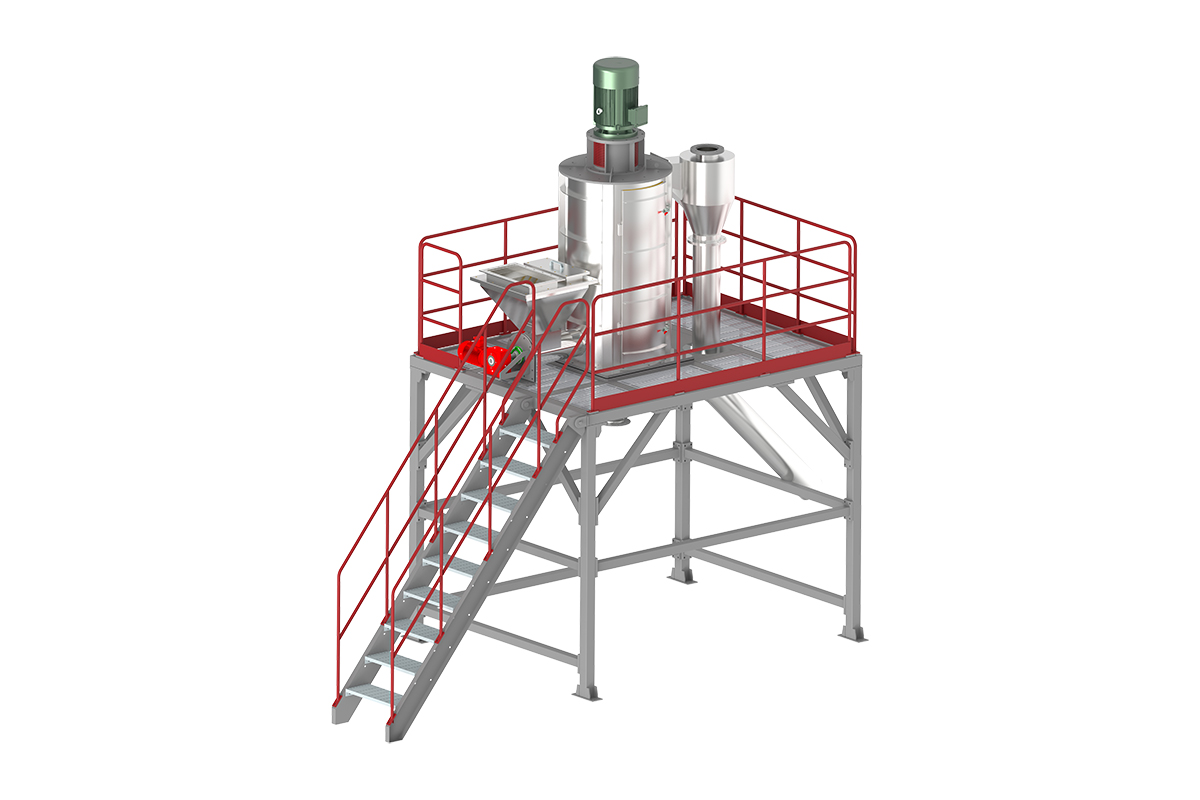

A separation machine is equipment designed to separate components of a mixture (solid-solid, solid-liquid, liquid-liquid, or gas-liquid) based on differences in physical or chemical properties (e.g., density, particle size, solubility, magnetic susceptibility). It is widely used in industries such as mining, food processing, pharmaceuticals, environmental protection, and chemical engineering to purify materials, recover valuable components, or treat waste.

Classification of Separation Machines

Separation machines are categorized primarily by the **type of mixture they handle** and the **separation principle** they rely on. Below is a detailed breakdown of common types:

Solid-Liquid Separation Machines

These machines separate solid particles from liquid (e.g., sludge dewatering, juice clarification) and are the most widely used category in industrial production.

Filter Press: Uses pressure-driven filtration, where solids are retained on a filter medium. It is commonly used in mining (for ore slurry dewatering) and wastewater treatment, offering advantages like high solid content in filter cakes and low moisture.

Centrifuge: Relies on centrifugal force to make denser solids settle to the machine’s wall. It is applied in the food industry (e.g., milk clarification) and pharmaceuticals (e.g., drug purification) due to its fast separation speed and high efficiency.

Vacuum Filter: Utilizes negative pressure to suck liquid through a filter medium. It is suitable for the chemical industry (e.g., crystal separation) and coal washing, as it enables continuous operation and meets large-scale production needs.

Sedimentation Tank: Operates on the principle of gravity sedimentation, where solids settle due to density differences. It is used in municipal wastewater treatment and drinking water purification, featuring low energy consumption and a simple structure.

Solid-Solid Separation Machines

These machines are used to separate two or more solid components (e.g., separating metal scraps from plastic, sorting different grades of coal).

Vibrating Screen: Separates solids by **particle size**. A vibrating sieve with different mesh sizes allows small particles to pass through, while large particles are retained. It is common in mining (for ore classification) and construction (for sand grading).

Magnetic Separator: Separates magnetic materials (e.g., iron, nickel) from non-magnetic solids using a magnetic field. It is widely used in recycling (sorting steel from household waste) and mining (removing iron impurities from ore).

Density Separator (Jig Separator): Relies on density differences. A water flow or air flow lifts lighter solids, while heavier ones settle. It is applied in coal preparation (separating coal from gangue) and mineral processing.

Liquid-Liquid Separation Machines

These machines separate immiscible liquid mixtures (e.g., oil and water, solvent and solution).

Decanter Centrifuge: Uses high centrifugal force to accelerate the separation of two liquids with different densities. An example application is separating oil from water in oilfield wastewater.

Liquid-Liquid Extractor: Relies on solubility differences—a solvent is added to the mixture to dissolve one component, and the two liquids are then separated. It is used in pharmaceuticals (extracting active ingredients from plant extracts) and petrochemicals (purifying crude oil).

Gravity Separator (Separator Tank): Utilizes gravity to let denser liquids settle at the bottom. It is often used for oil-water separation in restaurant wastewater.

Gas-Liquid/Gas-Solid Separation Machines

These machines purify gas by removing liquid droplets or solid particles.

Cyclone Separator: Uses centrifugal force to separate solid particles (or liquid droplets) from gas. The gas spins, and denser impurities are thrown to the machine’s wall and collected. It is common in power plants (removing fly ash from flue gas) and cement factories.

Demister: Removes liquid droplets from gas using a mesh or baffle. It is installed in distillation towers (chemical industry) or desulfurization systems (to prevent water vapor from entering gas pipelines).

Electrostatic Precipitator: Charges solid particles in gas with high voltage, then traps them on an electrode. It is used in coal-fired power plants (controlling dust emissions) and waste incineration plants.

Key Selection Factors for Separation Machines

Choosing the right separation machine depends on the following critical factors to ensure efficiency and cost-effectiveness:

Mixture Properties

For solid-liquid mixtures: Consider particle size (e.g., fine particles require centrifuges, while coarse particles use vibrating screens), solid content (high content may need filter presses), and liquid viscosity (high viscosity reduces filtration speed).

For liquid-liquid mixtures: Focus on density difference (small differences require centrifuges, large differences use gravity separators) and miscibility (only immiscible mixtures can be separated by physical methods).

Separation Requirements

- Product purity (e.g., pharmaceuticals require ultra-high purity, so centrifuges or membrane separators are preferred).

- Recovery rate of valuable components (e.g., mining needs high ore recovery, so magnetic separators or jigs are used).

- Treatment capacity (large-scale production requires continuous machines like vacuum filters; small-scale uses batch machines like filter presses).

Operational Conditions

- Temperature and pressure (high-temperature mixtures may require corrosion-resistant materials like stainless steel).

- Corrosiveness (acidic/alkaline mixtures need machines with anti-corrosion coatings, e.g., Hastelloy).

Cost and Maintenance

- Initial investment (centrifuges are more expensive than sedimentation tanks).

- Operating costs (including energy consumption and filter medium replacement).

- Maintenance difficulty (cyclone separators have simple structures and low maintenance; centrifuges require regular bearing checks).

Emerging Trends in Separation Machine Technology

With the development of green manufacturing and intelligent production, separation machines are evolving in the following directions:

High Efficiency and Low Energy Consumption

New designs (e.g., low-speed high-efficiency centrifuges) reduce energy use while improving separation efficiency. Membrane separation technology (e.g., ultrafiltration, reverse osmosis) is increasingly used for high-purity separation with low energy input.

Intelligent Control

Integration of sensors and IoT technology allows real-time monitoring of separation parameters (e.g., pressure, temperature, solid content). Automated systems adjust operating conditions dynamically to optimize performance (e.g., self-cleaning filter presses).

Environmental Friendliness

Use of eco-friendly materials (e.g., biodegradable filter media) and zero-waste designs (e.g., recycling of separation solvents) to reduce environmental impact. For example, in wastewater treatment, membrane bioreactors (MBRs) combine biological treatment with membrane separation to produce reusable water.

Miniaturization and Specialization

Small-scale separation machines (e.g., lab-scale centrifuges, portable oil-water separators) are developed for research, on-site testing, and emergency treatment (e.g., oil spill cleanup). Specialized machines (e.g., magnetic separators for rare earth metals) meet the needs of high-value industries.

In summary, separation machines are essential equipment for material purification and resource recovery across industries. Understanding their types, principles, and selection criteria is key to optimizing production processes and achieving sustainable development.

English

English