Single Shaft Shredder

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

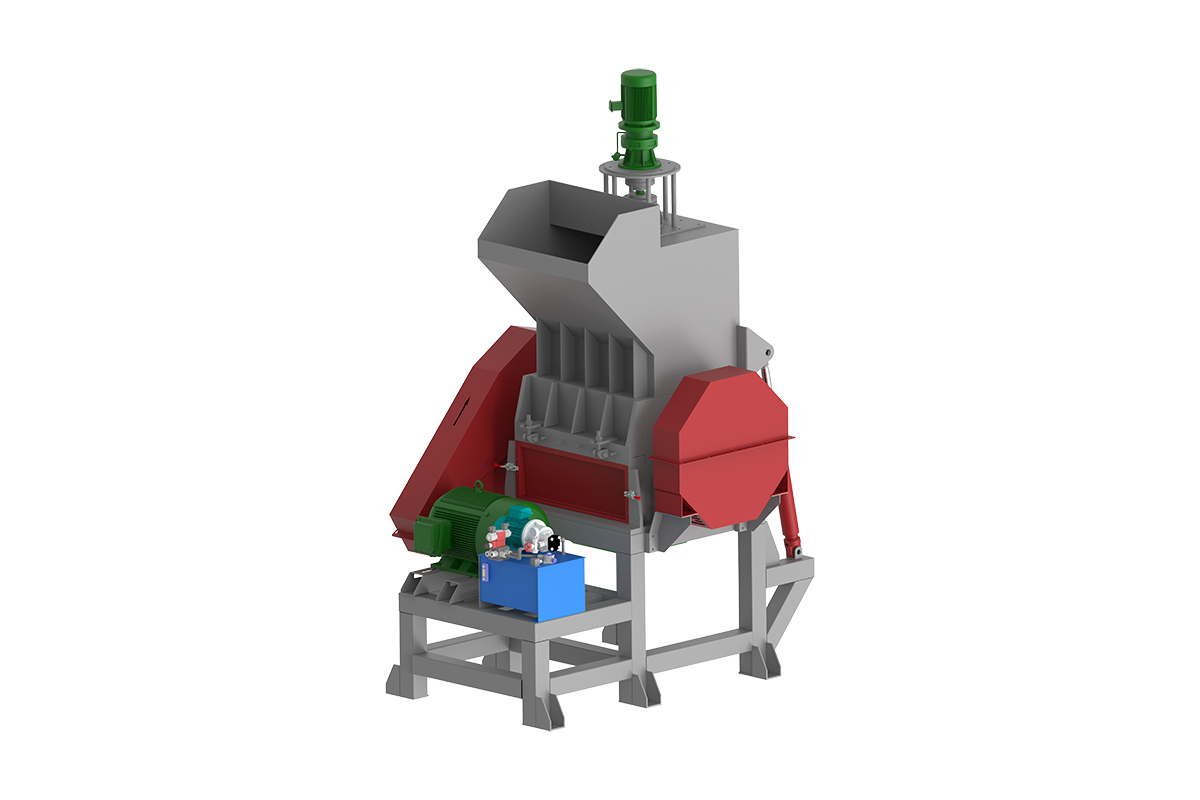

Single Shaft Plastic Shredder

- Product Details

- Basic Parameters

- Technical Specifications

Self-Pressing Plastic Bottle Shredder: Core Product Information and Advantage Analysis

As a key piece of equipment in the plastic solid waste recycling and treatment process, the Self-Pressing Plastic Bottle Shredder plays a vital role in the solid waste treatment processes of various industries, thanks to its targeted design and efficient crushing capability. The following is an explanation from four dimensions: core functions, application scenarios, working principles, and core advantages.

Core Function Positioning

Its core function is to perform efficient and uniform crushing of various plastic materials. It crushes large, irregular plastic raw materials or waste (such as plastic sheets, pipes, bottles, films, and injection molding scraps) into granular materials that meet the requirements of subsequent recycling and processing (e.g., granulation, recycling), providing pre-treatment support for the circular utilization of plastic resources.

Wide Range of Application Scenarios

This equipment has strong versatility and can meet the plastic solid waste recycling needs of different industries. Typical application scenarios include:

Packaging Industry: Crushing waste plastic packaging bags, express buffer plastic films, plastic foam boxes, and other packaging waste;

Plastic Product Manufacturing Industry: Handling scraps and defective products generated during production processes such as injection molding, extrusion, and blow molding (e.g., plastic part burrs, waste pipes, waste sheets);

Electronic and Electrical Industry: Crushing waste household appliance casings (such as plastic casings of refrigerators, washing machines, and air conditioners) and plastic packaging for electronic components;

Automotive Industry: Recycling and crushing waste plastic parts of automotive interiors (e.g., instrument panels, door panel plastics) and bumpers;

Domestic Solid Waste Treatment: Crushing plastic bottles, plastic basins, plastic toys, and other domestic waste discarded by residents in scenarios such as communities and waste treatment stations.

Core Working Principle

The equipment achieves crushing through a coordinated mechanism of "self-pressing + high-speed cutting", with the specific process as follows:

Material Self-Pressing Feeding: The self-pressing device equipped with the equipment (usually a material pressing mechanism at the feed inlet) exerts stable pressure on the input plastic materials to ensure that the materials fit closely to the crushing chamber, preventing incomplete crushing or jamming caused by loose materials;

High-Speed Knife Cutting: The core working component in the crushing chamber — high-speed rotating knives (mostly made of alloy steel, with high hardness and strong wear resistance) — rotate at a high speed (usually several hundred to several thousand revolutions per minute) driven by a motor. They perform rapid and continuous cutting and shearing on the plastic materials fixed by self-pressing;

Granule Screening and Discharge: The cut plastic granules are screened through a screen at the bottom of the equipment (the screen aperture can be replaced according to requirements). Granules that meet the particle size requirements are discharged directly, while larger granules that do not meet the requirements remain in the crushing chamber and continue to be crushed by the knives for a second time until they meet the set particle size standard.

Summary of Core Advantages

Wide Applicability: It is not restricted by the shape (block, sheet, tubular, film, etc.) or material (common plastics such as polyethylene PE, polypropylene PP, polyvinyl chloride PVC, and polystyrene PS) of plastic materials, meeting the crushing needs of multiple scenarios;

High Crushing Efficiency: The high-speed rotating knives combined with the self-pressing feeding design not only ensure stable material feeding but also quickly complete cutting, reducing material accumulation and increasing the crushing volume per unit time;

Good Granule Uniformity: By replacing screens with different apertures, the particle size of the crushed granules can be accurately controlled, ensuring uniform output granules and meeting the strict requirements for raw material particle size in subsequent granulation and recycling processing;

Facilitating Solid Waste Recycling: It directly meets the plastic solid waste treatment needs of various industries, converting waste plastics that were originally difficult to recycle into reusable raw materials, reducing environmental pollution caused by plastic waste, and conforming to the development trend of green environmental protection and resource recycling.

| Model | Motor power(kw) | Hydraulic station power(kw) | Diameter(Ф) | Speed(r/min) | Screen aperture(mm) | Weight(kg) |

| 800 | 45kw | 0.75kw | Ф570mm | 530r/min | Customizable | 2020kg |

| 1000A | 55kw | 1.5kw | Ф620mm | 556r/min | Customizable | 3250kg |

| 1000B | 55-75kw | 1.5kw | Ф680mm | 556r/min | Customizable | 3850kg-3950kg |

| 1200A | 75kw | 1.5kw | Ф660mm | 556r/min | Customizable | 4800kg |

| 1200B | 90-112kw | 1.5kw | Ф800mm | 556r/min | Customizable | 5050kg-5320kg |

| 1600 | 162kw | 3kw | Ф800mm | 500r/min | Customizable | 6500kg |

● Materials: Both the housing and blade holder are made of 45-gauge steel for high strength and resistance to deformation.

● Sturdy mortise and tenon welded steel structure.

● Manganese steel screen for wear resistance.

● Heavy-duty pulleys.

● Hydraulic flap for easy access and maintenance.

● Different blade roller configurations maximize productivity and service life.

● Drum types: Splayed blade roller, Slotted blade roller, Hanako blade roller, etc.

English

English