Sinlg/Double Screw Washing Tank for Pet Flakes

Contact Us

E-mail:sales@dgsaiko.com

tel:+86-137 2820 8855

Address: No.7, Industrial North Road 3, Chikan Village, Shipai Town, Dongguan City, Guangdong Province, China

Double-Layer High-Speed Friction Machine

- Product Details

- Basic Parameters

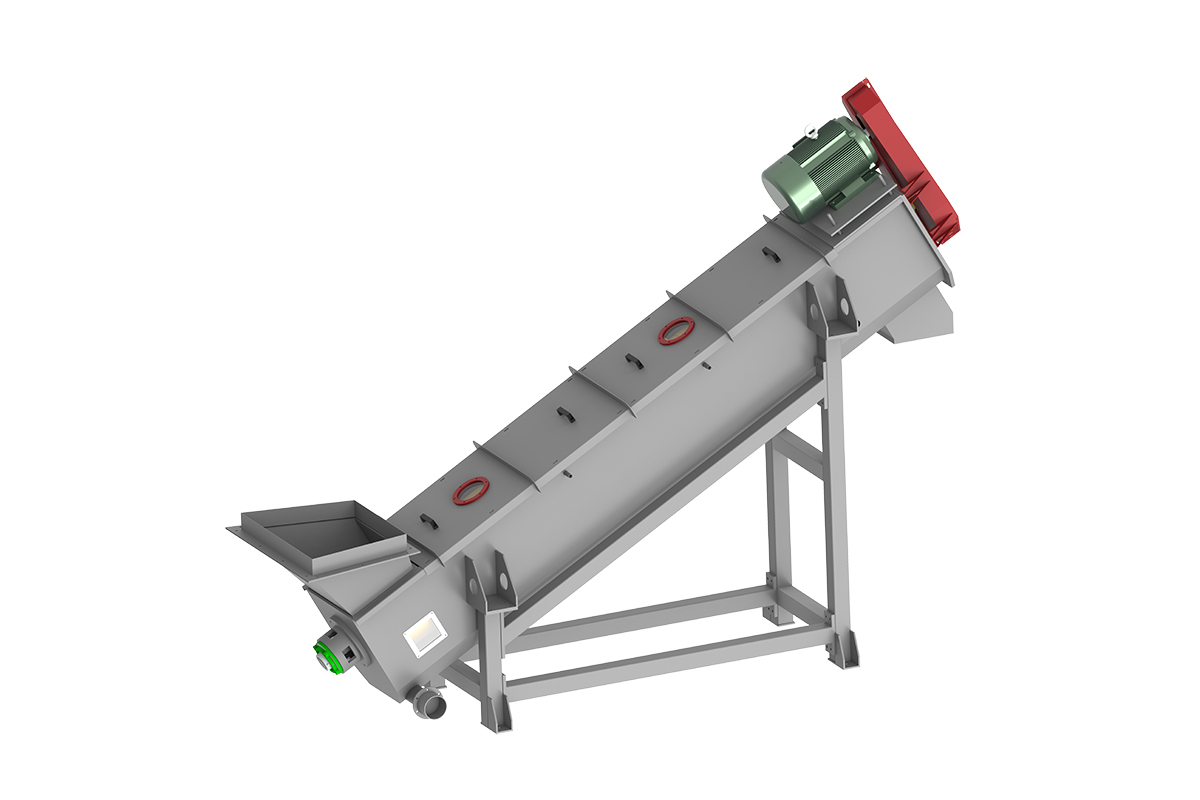

Introduction of Double-Layer High-Speed Friction Machine

Double-Layer High-Speed Friction Machine is an efficient material cleaning equipment, mainly used to remove various impurities such as sediment, oil stains, pulp, and cleaning agents attached to materials, and can quickly separate sewage from raw materials. Its detailed introduction is as follows:

Working Principle

The core of the double-layer high-speed friction machine is a high-speed rotating main shaft, on which many inclined blades or paddles are installed. When materials enter from one end of the equipment, driven by the main shaft, the blades rotate at a high speed, making the materials form a high-speed rotational movement in the machine body. Intense friction occurs between materials, as well as between materials and blades and the inner wall of the machine body, thereby stripping off the impurities attached to the material surface. At the same time, the equipment adopts water jets and nozzles to spray water, which fully mixes water with materials to further enhance the cleaning effect. The stripped impurities are discharged through the screen of the double-layer full-screen structure along with the water flow, while the cleaned materials are discharged from the other end of the equipment.

Structural Features

Double-Layer Full-Screen Structure: This structure can more effectively separate sewage and raw materials. Sewage and impurities can be quickly discharged through the holes of the screen, while raw materials are intercepted by the screen and continue to be cleaned in the equipment or transported to the next process, improving cleaning efficiency and separation effect.

Precision-Machined Main Shaft: The precision-machined main shaft can ensure the stability and accuracy of rotation, reducing equipment wear and poor cleaning effects caused by main shaft vibration. At the same time, it helps to extend the service life of the equipment.

High Wear-Resistant Blades: Since the blades are in frequent contact with materials and impurities during operation, they need to have high wear resistance. High wear-resistant blades can reduce the wear rate of the blades, lower the maintenance cost and downtime of the equipment, and ensure the continuous and efficient operation of the equipment.

Application Fields

The double-layer high-speed friction machine is widely used in the plastic recycling industry and can be used to clean crushed waste plastic sheets and plastic films, such as agricultural mulch films, cement bags, and convenience bags. In addition, in some industries such as mineral processing and wood processing, it also plays an important role in cleaning materials that need to have surface impurities removed.

| Model | Diameter(Ф) | Motor Power(kw) | Speed(r/min) | Screen length(mm) | Weight(kg) |

| 350 | Ф410mm | 22kw | 770r/min | 2250mm | 1512kg |

| 400 | Ф440mm | 22-37KW | 770r/min | 3000mm | 1685kg |

English

English